● Excellent molding stability

The servo driving system has its pressure and flow under closed

loop control; and compared with traditional injection molders, its

molding repetition precision is improved substantially

● Constant oil temperature

The servo motor output hydraulic oil proportionately to prevent

excessive heat.It can achieve substantial water saving even without cooling.

● Rapid response

The servo driver features rapid response whose rapid starting time

is improved by 50% compared with traditional injection.

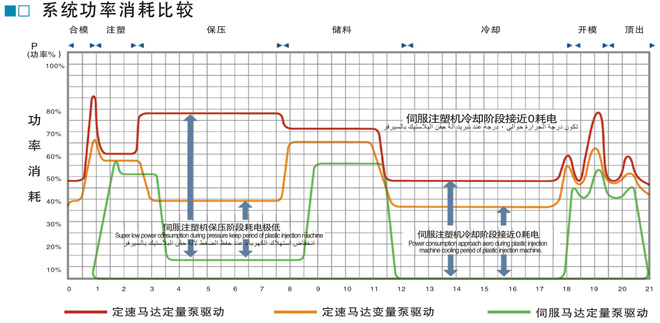

● Substantial energy saving

Under the same conditions, it can save 20%-80% energy compared with traditional constant delivery pump injection molders.

● High performance environmental protection

The complete machine features low operating noise, and even quieter during low-speed operation

Technical parameters of the one-piece machine

| 说明 DESCRPTION | UNIT | HS-788 | |||

| 国际公认型号 INTnternational Szize Rating | 5820 | ||||

| 注射装置 Injection Unit | A | B | C | D | |

| 螺杆直径 Screw Diameter | mm | 90 | 95 | 105 | 110 |

| 螺杆长径比 Screw L/D Ratio | L/D | 23 | 21 | 20 | 18.5 |

| 理论注射容积 Theoretical shot volume | cm3 | 2990 | 3331 | 4070 | 4467 |

| 注射重量 Shot Weight(PS) | g | 2721 | 3032 | 3703 | 4065 |

| 注射压力 Injection Pressure | Mpa | 194 | 174 | 143 | 130 |

| 螺杆转速 Max.screw speed | rpm | 110 | |||

| 锁模系统 Clamping Unit | |||||

| 锁模力 Clamping Forec | KN | 8000 | |||

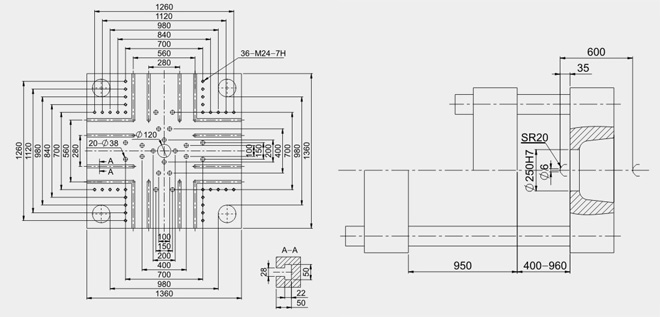

| 开模行程 Opening Stroke | mm | 950 | |||

| 拉杆内间距 Distance Between Tie-bars | mm | 980×950 | |||

| 最大模厚 Max.mold Height | mm | 960 | |||

| 最小模厚 Min.mold Height | mm | 400 | |||

| 顶出行程 Ejector Stroke | mm | 280 | |||

| 顶出力 Ejector Force | KN | 210 | |||

| 其它 Others | |||||

| 电马达功率 Drive power | KW | 37+37 | |||

| 电热功率 Heating capacity | KW | 54.3 | |||

| 外形尺寸 Machine Dimensions | m | 11.43×2.40×3.14 | |||

| 机器重量 Machine Weight | t | 42 | |||

Template dimensions

Clamping part

Haishi creates independently the box type high rigidity mold

structure for the clamping part; the clamping support guide rail adopts

the high rigidity design to reduce the deformation effectively; the

toggle structure optimized and designed with computer achieves

exceptionally stable and rapid clamping; and the enlarged mold

thickness, the gear mold regulation unit and the internally installed

mechanical safety lock as well as the 180-degree rotary product blanking

bucket, all help achieve your individual demands and make your

operation easier!

● The original box type high rigidity template with template`s small

template deformation and pull rod’s long service life can ensure the

performance of die assembly.

● The original box type high rigidity template with template`s small

template deformation and pull rod’s long service life can ensure the

performance of die assembly.

● The internally-installed cascade mechanical safety lock will not be

influenced by the mold thickness deformation,and the mechanical

locking bar has been changed from the traditional compressive type to

the tension type,so it is convenient and reliable in use.

● The gear mold regulation unit can regulate mold precisely and with good synchronism.

● The clamping support guide rail uses joist steel structure

with high rigidity in order to lower the deformation of the rack.

●

The toggle structure optimized and designed with the computer

program,cooperating with the regulation of 4 stages and flow during

opening and clamping mold of the controller,in order to achieve

exceptionally stable and rapid clamping.

● Rotary product blanking bucket can adapt to the workshops and products can be taken out from different places.

● The differential motion clamping unit can improve the mold transferring speed and productivity substantially.

● Ejector pin adjustable unit

Injection unit

● Double cylinder injection: it overcomes the weakness of the

traditional  non-synchronous injection motion and great inertia, makes

the injection and transferring motion more stable and improves the

injection precision up to 98.75%.

non-synchronous injection motion and great inertia, makes

the injection and transferring motion more stable and improves the

injection precision up to 98.75%.

● The folding type swabbing and injection oil cylinder: it

is more compact than the traditional double cylinder structure with

reasonable energy consumption allocation./p>

● The ship type bridge guide rail: the injection and

transferring adopts the ship type bridge guide rail design with low

noise and smooth travel; it is suitable for high speed application; and

it can maintain the precision for a long time featuring high locating

precision and good repeatability.

● Oil seal: it uses non-rotary sealing technique to prevent leaking.

● The regulation unit at the center of the nozzle: it regulates the nozzle center more conveniently and accurately.

● The rigid connection between injection motion and control

valve, in order to lower the fluctuation of the fluid and improve the

injection precision.

Hydraulic unit

The oil way design of big bore under no resistance can lower

the oil way loss and noise;  it uses the advanced configuration, the

servo control system, so it features energy saving capacity up to 20-80%

and can achieve zero back pressure glue-smelting with plasticizing

capacity and plasticizing effect improved by 60% compared with the

traditional machine; and it uses a high density filtering unit in order

to control the greasy dirt at NASB-9.

it uses the advanced configuration, the

servo control system, so it features energy saving capacity up to 20-80%

and can achieve zero back pressure glue-smelting with plasticizing

capacity and plasticizing effect improved by 60% compared with the

traditional machine; and it uses a high density filtering unit in order

to control the greasy dirt at NASB-9.

● The advanced configuration, the servo system, can save energy up to 20-80%.

● It uses the high pressure filter screen in order to control the greasy dirt at NASB8-9.

● 60 um filter screen has a super strong capacity of receiving pollutant which can be replaced easily.

● The zero back pressure glue-smelting unit improves

plasticizing effect and plasticizing capacity by 60% compared with

common molders.

● According to the fluid simulation analysis, the design of

optimized oil way can achieve a large bore and non-resistance, so its

pipeline loss is more than 10% lower than the traditional design and its

overall unit noise is more than 6 db lower.

● The new type of oil tank design is in favor of air’s

separation, in order to ensure good operation of the servo system, and

it is convenient for cleaning.

Electric control unit

The whole control system of the injection molder features

powerful function and stable  performance with high speed response. The

controller is a new type of controller which is co-developed with a

renowned injection molder computer supplier under the hosting of the

professional and technical personnel of our company. It uses high speed

stable DSP technique, combining with 16 bit high speed analog quantity

input, in order to achieve more precise data detection box control; its

display uses high resolution LCD display, featuring advantages far above

the common computers.

performance with high speed response. The

controller is a new type of controller which is co-developed with a

renowned injection molder computer supplier under the hosting of the

professional and technical personnel of our company. It uses high speed

stable DSP technique, combining with 16 bit high speed analog quantity

input, in order to achieve more precise data detection box control; its

display uses high resolution LCD display, featuring advantages far above

the common computers.

● High resolution color TFT LCD display

● Internally installed multiple language choice

● The operation interface of Windows style has the

function of a oscilloscope which can display the injection speed and the

pressure maintaining pressure curve

● 16 bit high speed AD to make the position measurement of electronic ruler more accurate

● The internally installed lntel 400 MHz high speed CPU control system can achieve high speed response

● The 64M RAM system memory for preservation of different sets of mold data

● It has MMC/SD card port for convenient copying or storage of data.

● The production data recording and monitoring function for the convenience of technical adjustment

● It is equipped the with mechanical arm electrical interface

which can be used to match the special mechanical arms for the injection

molders from home and abroad.

Our advantage

It is a perfect injection molder for most components, thin-wall

and thick-wall injection molding as well as many standard applications. A

wide range of standard functions and multiple options can meet all

kinds of your needs. Moreover, our veteran Haishi technicians devote

themselves to meeting the special demands of the customers every day.

High-quality Haishi injection molder features super low maintenance

ratio, which can improve the productivity of the user substantially.

●Exceptionally high precision and long service life.

The knuckle joint high speed clamping mechanism of the optimal

design lowers the pressure stress at the joint, to ensure the

exceptionally high precision and long service life of the machine.

●Neutron/ height-adjustable camper control

Flexible neutron programming control and independent hydraulic pump station to supply power.

●Extra-wide template design and larger mold scope

The high capacity and wide template design satisfies the scope

of the customers’ choices of the mold to the maximum limit.

●High quality system central lubrication

High performance thin oil central lubrication, moving parts

wearing lowered sharply and locating precision of mold kept for a long

time.

●Convenient product delivery

Take out plastic products from different places and use the

equipment space efficiently, so it is suitable for the installation of

different

●kinds of conveying equipment.

Mobile waste oil cleaning tray makes it convenient to clean the waste oil in the die assembling area.

●High-end controller

Use high performance full computer special controller with large window, color display and complete functions.

Service is everywhere – our eternal belief.

Service runs through the processes of the whole core business of

Haishi as well as equipment manufacturing and marketing. It is required

by the market competition that added value should be provided and that

the customer service also becomes more important. Haishi’s service is

comprehensive from the beginning to the end in order to provide complete

pre-sale consultation, sales support and after-sale services. No matter

how long your machine is used, all users of Haishi will enjoy our

lifetime maintenance service.

● Dedicated technical team:The technical team of Haishi Co. has

enjoyed a good reputation in the injection molder industry for more than

20 years: we don’t only develop and manufacture machinery meeting the

market needs, but lead the customers to the more efficient,

energy-saving and high quality realm through our abundant technical

foundation.

● General information center:The core business of Haishi

technical team is to help the customers overcome difficulties of

injection molding; and to provide comprehensive suggestions and

solutions. We analyze the difficulties of a project in an all-round way

for the customers and recommend machinery meeting the requirements of

the project. The whole proposal gives consideration to economical

efficiency, precision and high efficiency as well as the development

tendency of the future market, so the customers can order according to

their purchasing power and actual demand.

● Timely after-sale service:Haishi owns a modern management

system; and we will notify our cooperating agents and the service staff

on the first line of a service request as soon as possible, and they

will arrive at the site to solve the problem without delay.

● Complete training project:Each cooperating agents of Haishi

injection molders will provide complete training services for our

customers, in order to help them know more about our machine as well as

their proper operation and maintenance. The senior engineers from the HQ

of Haishi will also pay visits to our users regularly, make good

investigation on the use of the customers and update the machine

according to the feedbacks from the customers, in order to make our

machine more adapting to the requirements of the customers.

● Timely global distribution:The level of after-sale service

depends on the supply speed of parts; and Haishi offer the service 7

days each week and 24 hours each day. Our HQ and cooperating agents all

have sufficient inventory of regular parts; for special parts, we

receive the order on the same day and distribute them without delay, in

order to help the customers resume production as soon as possible.

Innovative mechanical design, humanized control and good mechanical performance